What is Autostore?

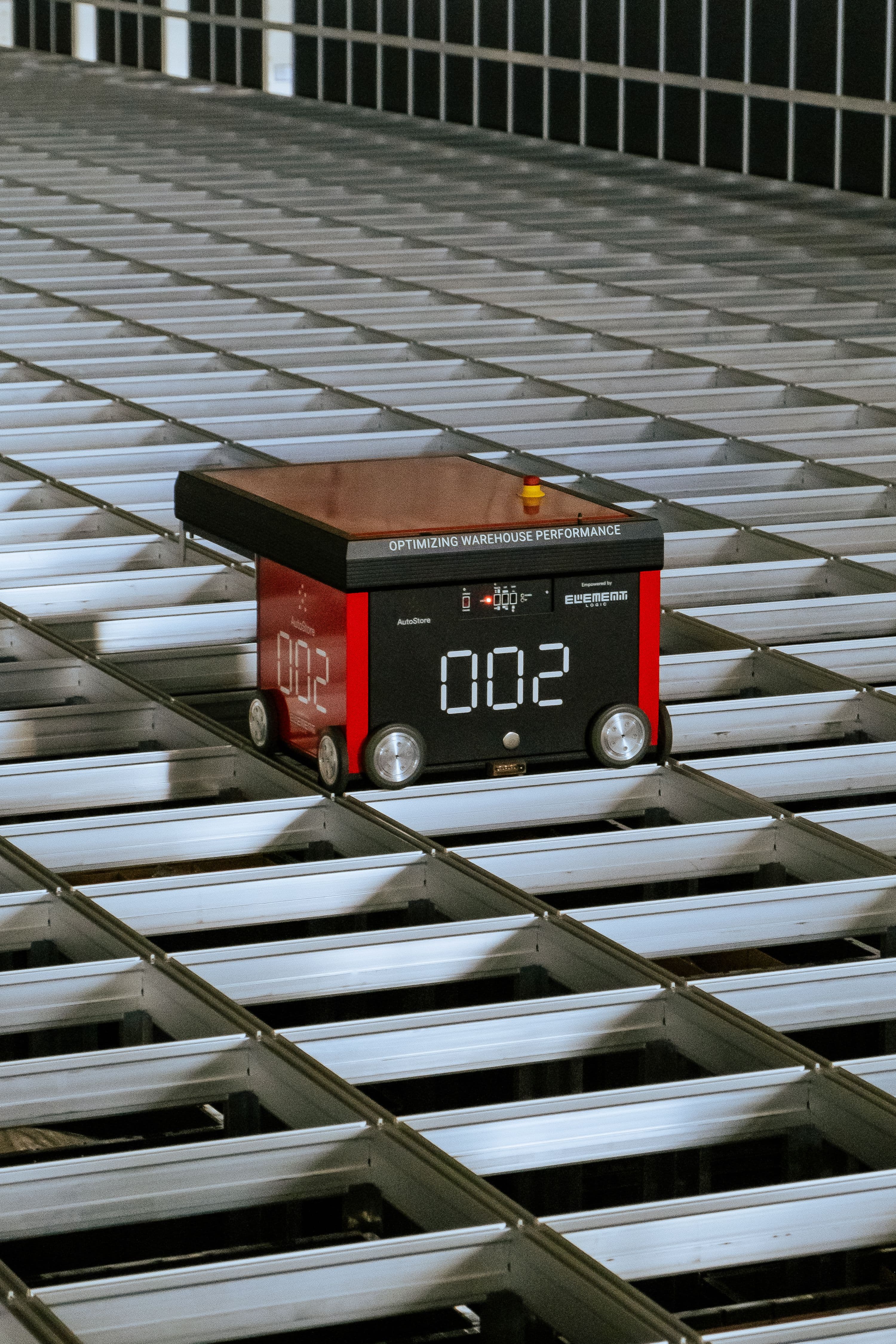

Autostore is a robot-controlled warehouse management system.

Automated storage systems are popular in industries such as e-commerce and retail, where the need for fast and accurate picking of goods is crucial. The system is designed to maximize storage capacity and increase the efficiency of the picking process.

Autostore uses a cube-shaped storage structure where the robots move on top of the cube. This allows a very high degree of space utilization, as the storage cubes can be placed close together without the need for human walkways.

When an order is to be picked, the Autostore robots retrieve the boxes with the required goods and deliver them to a port, where the warehouse workers can easily pick from.

Fast and accurate order handling

Benefits of Autostore at a 3PL

Autostore is a scalable system. You can easily add more bins, robots and gates to handle increasing volumes and storage needs.

The use of Autostore can therefore have a major impact on both precision levels and efficiency. By working with a 3PL that uses Autostore, you gain access to a number of benefits, including

- Efficient pick & pack processes: The robotic warehouse delivers directly to the picker, saving time and reducing errors.

- High precision: Barcode-based picking and quantity confirmation ensures accuracy at every stage.

- Cross-docking: Goods can be quickly handled and further distributed without the need for unnecessary storage.

- Parallel operation: Ability to receive goods at the same time as orders are sent out.

Maximized Storage Utilization

Cost-Effective Storage with Autostore

From a cost perspective, there are several advantages to an automated warehouse like Autostore:

- Goods are stored compressed in 70-liter boxes with dimensions of 60x40x30 cm.

- The boxes are divided into compartments from 1 to 16, so you don't pay for more than you use. In a 1/16th location, you pay 1/16th of the daily price for a full box.

- Distribute goods across multiple loactions so that the checkout is released more often.

- Dynamic calculation of warehouse rent at 24-hour level: You pay nothing the day after checkout.

- Rolling inventory counting, which means that you can count locations that have not been confirmed in the last calendar year.

- The goods are very safe as you cannot go inside the cube.

All in all, Autostore provides efficient storage, which in turn helps to keep storage costs as low as possible.

Integration with your system with Autostore WMS

Our Warehouse Management System (WMS) is tightly integrated with Autostore.

This ensures a seamless flow from goods reception to dispatch. This integration is crucial for efficient 3PL services, as it provides real-time data on inventory status, order processing, and item movements.

We are also actively driving the development of new functionality in the WMS, ensuring that you, as our customer, have full visibility and benefit from our continuous process improvements.

360 Logistics customizes Autostore for your online store

Whatever the scale of your online store or logistics needs, we ensure you get the most out of our robotic warehouse.

We achieve this by carefully evaluating how to store goods in the robotic warehouse, ensuring an optimal balance between storage and picking efficiency. Examples of different storage strategies include distributing single SKUs across multiple locations and utilizing various location sizes depending on the specific SKU requirements.

Many customers require customizations, such as branded packaging, flyers, thank-you cards, stickers, and similar items. We address this by tailoring the ports to meet the specific needs of each customer.

Challenges of a Robotic Warehouse

While Autostore offers high levels of automation, it still requires human operation and comes with inherent limitations. Improper use can create bottlenecks in outbound production.

Key considerations to keep in mind:

- Users of Autostore must understand the correct allocation flow to prevent bottlenecks.

- Efficient processes outside the port are crucial.

- Adequate port capacity is essential.

- Sufficient robot capacity is necessary.

No matter how quickly the operator at the port works, there will always be a limit to how many bins each port can handle in a day. To avoid the system itself becoming a bottleneck, it’s essential to have enough port capacity.

At the same time, the more ports in operation, the more robots are needed to manage the facility efficiently.

Save investment costs

The benefits of outsourcing logistics

Gate and robot capacity entails significant investment costs.

For many retailers, it can be smart to outsource the logistics and management of Autostore to a specialized third party. In this way, you can benefit from technology and an automated warehouse, while only paying for what you use at any given time.

Are you looking for a logistics partner?

Get in touch for personal follow-up and help with your logistics.